Can your inverter handle the heat?

Summer is fast approaching and though that means more hours of sunshine, for most of the U.S. it also means hot days and plenty of them. A well-known fact about PV arrays is that as temperature rises, system voltage drops and can fall dangerously close to the lower edge of the Maximum Power Point Tracking (MPPT) window.

As heat raises in extreme environments and voltage subsequently drops, inverters must adjust the maximum power point (MPP) they track to account for the change on the IV curve. A justified concern is that this could cause an inverter’s MPP to drop below the lower MPPT voltage window and the inverter would disconnect and stop producing power.

Avoiding the issue

Sunny Boy inverters are able to manipulate the PV array’s voltage to maintain an MPP slightly higher than the lower MPPT voltage window by reducing the array’s current. The inverter will continue to do this until it can no longer keep the power above its preset minimum power (Pmin) threshold, which typically happens during sunset.

For example, the Pmin for a Sunny Boy 10000TL-US is 700W. The inverter, chosen because of its high efficiency yet comparably narrow voltage window, will continue to reduce the array’s current to keep the voltage above the lower MPPT value (300VDC on a 208V service) until the AC power reaches 700W, then the inverter will disconnect from the grid, go to sleep and start again the next day.

How it works

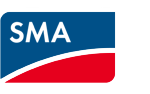

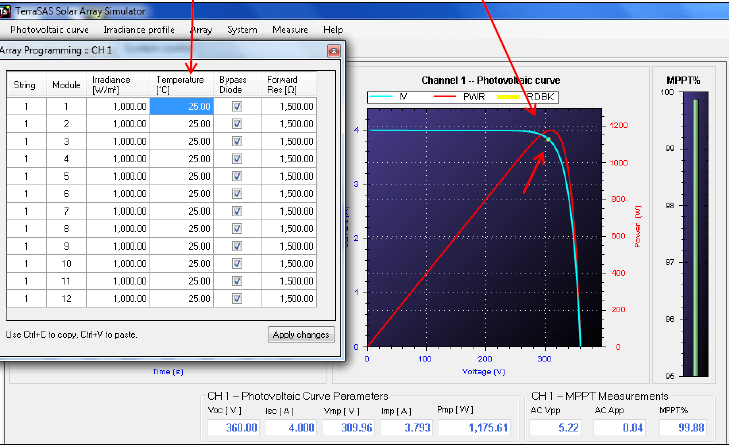

Using the Solar Academy’s TerraSAS simulator, which we’ve previously discussed, we can observe the behavior of SMA’s Optitrack MPPT in action the Sunny Boy 10000TL-US connected to our 208V service.

Figure 1 shows normal operation; the IV curve for an array has one string, 12 modules, and a module open circuit voltage (Voc) of 30V. The inverter is tracking right at the MPP, shown here as a small yellow box. The array is at standard testing conditions with irradiance at 1000W/meter2, temperature is 25°C (77º F) and the inverter is producing 1174W of power. The inverter’s MPPT algorithm is performing well above 99 percent accuracy, very impressive.

Figure 2 shows the manipulations in the IV and power curves when we increased the simulated temperature to 50°C (122° F), very hot and very possible in parts of the country. The MPPT moved down the IV curve to about 300V, though the actual MPP is slightly higher on the curve. The Sunny Boy has reduced the PV array’s current to maintain an MPP more than the low point of the MPPT voltage window. Because of this intelligent operation, the accuracy of the MPP suffers slightly but plenty power is being produced where other inverters might shut off.

It’s important for system designers to look at the potential for, or frequency of, heat-related low voltage power losses; these considerations can greatly impact system configuration and inverter sizing. Not every part of the U.S. will experience the high temperatures needed to cause this balancing act, but many parts of the South and Southwest should consider heat and voltage when designing or retrofitting a system.

Feel free to contribute!