String versus Micro – Which is the Right Choice?

When it comes to making decisions about a PV system, one of the most common decisions a system owner has to make is whether to choose a micro inverter or a string inverter. As one of the only inverter manufacturers globally to offer a full range of micro, string and central inverters, SMA is best placed to understand the difference between each of these products and technologies, and provide the product best suited to each specific application. Below we discuss a number of factors related to PV systems and the relative advantages of both micro and string inverters to help make the right technology choice for each individual application.

Grid Support Functions & Install Flexibility

Where local grid operators require the PV system to have grid support functions such as reactive power, specific power factor correction set points, low voltage fault ride through or export control, string inverters are the best option. SMA’s current model string inverters all have the ability to provide varying levels of grid support dependent upon the individual requirements of the system and grid operator. Micro inverters are not able to provide the same level of grid support, yet.

For system installs on tricky roof structures, or where sub-sections of a PV array need to be separated or installed on different orientations, a micro inverter can represent the simplest and lowest cost system. Since micro inverters are AC coupled and individually track their PV module’s maximum power point, they are more flexible in how and where they can be installed compared to DC coupled PV panels and a string inverter.

PV Array Oversizing

Oversizing the PV array is a tool used by system designers and installers to improve the performance of a PV system while reducing the specific cost in $/W. It involves installing a DC rated capacity greater than the inverter’s AC rating. It is possible to do this because under normal operating conditions, a PV array rarely achieves its rated output (mostly due to voltage dependant temperature de-rating). Oversizing the PV array makes better use of the inverter’s rated capacity and increases the energy output from a PV system. String inverters are the simplest, most suitable and lowest cost option for oversizing, because all that is required is to either increase the length of the PV module strings, or increase the number of parallel strings.

It is also possible to take advantage of oversizing when using a micro inverter system, however, it will typically result in a much higher specific $/W investment. To oversize a PV array using micro inverters requires the use of higher power PV modules. Since these modules typically attract a premium price compared to standard power PV modules, the overall system cost will be higher for a similar performance benefit compared to an oversized array with a string inverter.

Performance & Shading

Under normal unshaded conditions, a string inverter will typically offer the lowest cost and greatest energy yield. For varying degrees of partial shading of the PV array, a micro inverter can offer slightly higher performance (~1 – 4%).

Under normal un-shaded conditions, a correctly sized string inverter system will typically outperform a correctly sized micro inverter system by ~0.5%. Micro inverters are able to reduce some very small losses such as DC cabling and any module mismatch, but they have a lower operating efficiency. Put together, this means string inverter systems will typically outperform micro inverter systems in normal un-shaded conditions.

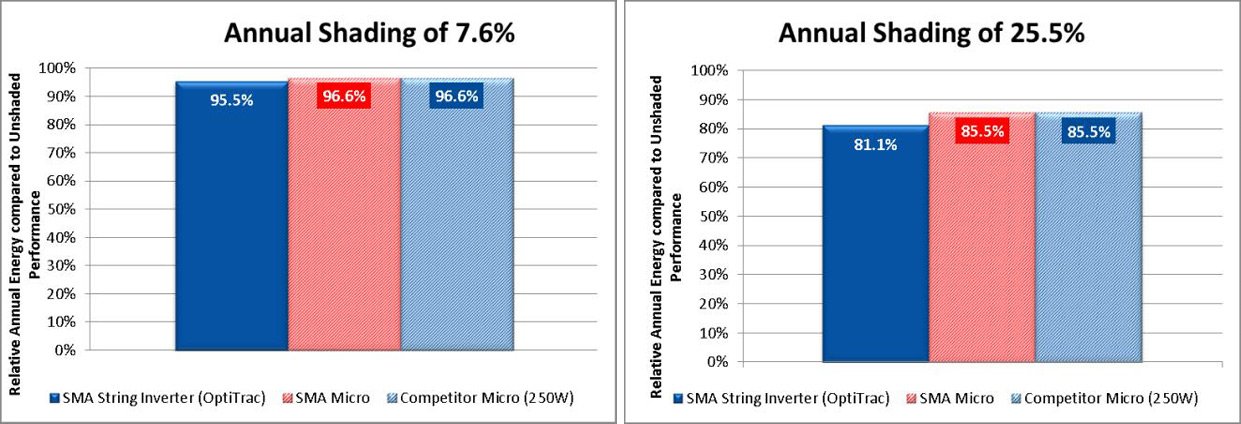

Under permanent or partial shade conditions, the answer is more complicated. To help understand these complicated factors, SMA commissioned a US based independent PV research laboratory (PV Evolution Labs) to investigate the effect of shade on system performance. The study compared a variety of shading conditions on the performance of a:

- SMA Transformerless string inverter with OptiTrac Global Peak;

- SMA micro inverter;

- Leading competitor’s micro inverter;

Under all shading conditions, both micro inverters and the string inverter with OptiTrac Global Peak performed almost identically. Some of these results are summarised in the graphs below.

SMA’s patented OptiTrac Global Peak maximum power point tracking algorithm significantly improves the performance of string inverters under shaded conditions. Under light shading (7.6 %), micro inverters only outperform a modern string inverter by ~1% (annual energy yield). While under heavy shading conditions (25.5%) the annual energy yield difference is ~4%. The value of this energy to the system owner needs to be considered when making a system decision, specifically whether a 1 – 4% energy yield increase from micro inverters offsets the higher $/W cost to install.

System Monitoring

String and micro inverter systems are able to connect to SMA’s free online monitoring platform, Sunny Portal. There are differences in the monitoring and display capabilities within Sunny Portal for micro and string inverter systems.

For systems requiring PV panel level monitoring, a micro inverter system is a very simple option. PV panel level electronics allow the individual performance of each PV panel to be known and displayed. This information can be useful in situations where the system operator requires the individual operating performance of each PV panel.

Features available for both micro and string inverter systems registered on Sunny Portal include: live system performance, automated reporting functions for daily, monthly and yearly performance, fault and error reporting, remote service capability, local visualisation through smart devices, future energy predictions and automated load control.

Service & Reliability

Reliability of a PV system is essential to deliver energy and financial benefits to the system owner. Minimising the service risk of inverters is the largest factor affecting overall system reliability and economic performance. When deciding between micro or string inverters, two of the following questions need to be addressed.

1. How many failures is the system likely to experience during its lifetime?

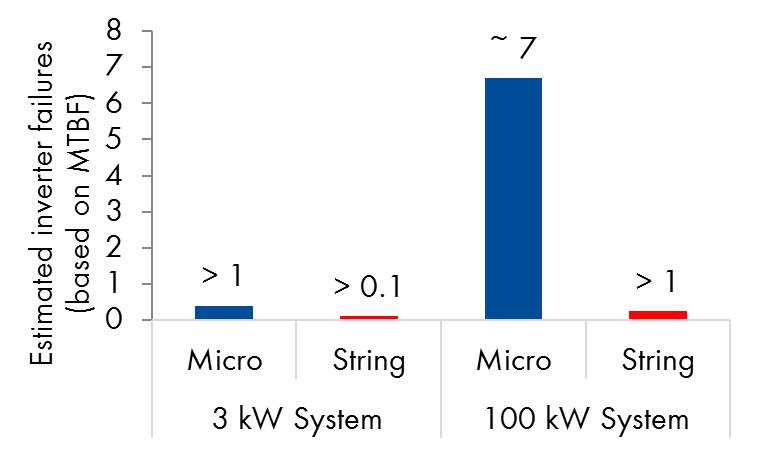

Calculating failures in power electronics is directly related to the number of components in the collective devices, and the temperature and humidity at which those components are forced to operate. So if a system has a greater number of components or operates at higher temperature and humidity, statistically it is more likely to fail. SMA has developed its micro inverter to have the fewest number of components (less than 50 %) compared to competitor micro inverters on the market. And while a single micro inverter has fewer components than a single string inverter, the more micro inverters there are in a system, the more likely that system will statistically experience a failure.

Mean time between failure (MTBF) is a statistical measure used to estimate likely inverter failures in a system over its warranty period. In the graph adjacent, an MTBF of ~300 years for micro inverters and ~150 years for string inverters has been assumed for the purpose of comparison (since SMA do not publicly quote MTBF statistics, values used are based on those commonly quoted by other inverter manufacturers). For a 3kW PV system, a micro and string inverter system are statistically likely to experience the same number of inverter failures during the warranty period (i.e. ≤ 1 failure). However if the same statistical process is applied to a 100kW PV system, a micro inverter system is statistically likely to experience a higher number of individual inverters failures compared to the string inverter system during the warranty period.

2. What will it cost to service or replace an inverter?

It is difficult to estimate the cost to service or replace a failed inverter as there are many important factors which need to be considered. From the inverter point of view, SMA provides replacement inverters where an inverter has not met its warranty obligation, and also provides a rebate to installers that perform warranty replacements. However the costs to service a micro inverter or string inverter may be different. Replacing string inverters will typically only require ground access to a site. Depending on the weight of the inverter and tools available, replacing a string inverter can typically be carried out by a single installer. Replacing micro inverters can be more difficult and time consuming. Replacing means access to the roof will always be required and accessing such spaces typically requires two people for safety reasons, and special equipment such as a roof harness. Additional costs associated with replacing micro inverters can include locating and accessing the failed inverter, removing the connected PV module, and replacing array framing earthing plates.

With regard to service and reliability, for a system size of ~3kW or less, both micro and string inverters are suitable solutions. For systems larger than 3kW, the lowest cost and most reliable solution is to use string inverters.

System Payback

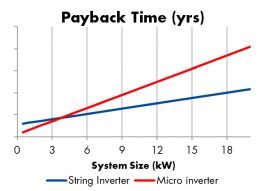

Once a system exceeds ~3kW in size, a string inverter will typically deliver a shorter payback time compared to a micro inverter system.

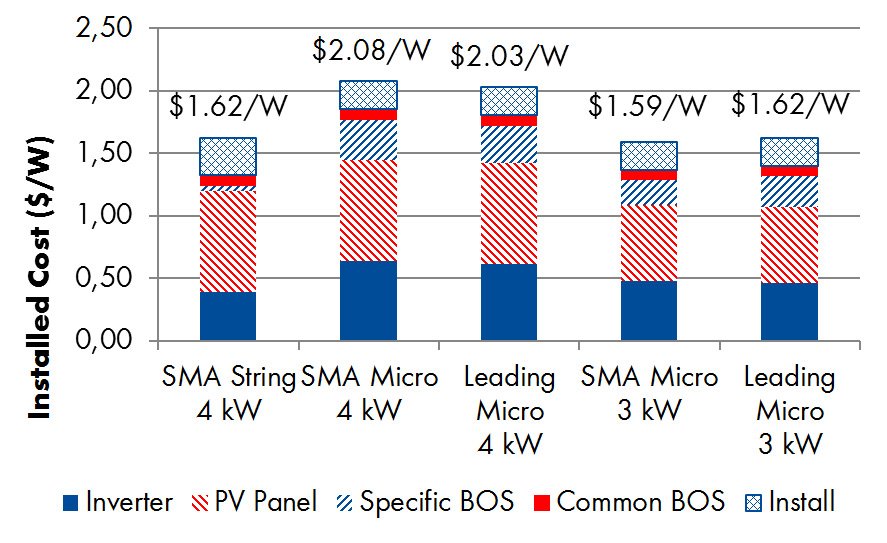

Micro inverters are more expensive than string inverter on a $/W basis. However their use can remove the requirement for other system components (e.g. DC isolators, HD conduit, earth fault alarms, etc). This means for small PV systems, the total installed cost of a PV system can sometimes be cheaper using micro inverters rather than string inverters. However as systems get larger, the cost of these additional components required with string inverters can be amortised across a greater number of kW. This slowly tips the economics and shortest payback time in favour of a string inverter solution.

Another issue to consider is the relative benefit of installing a smaller micro system, or a larger string inverter system. For example, it is a lower cost option to install a 4 kW string inverter system than to install a 3 kW micro inverter system. In addition to the initial cost benefit, a 4 kW string inverter system would yield ~25% more energy compared to a 3kW micro inverter system. Some of these economics are presented in the graph following.

For PV systems greater than 3 kW, and for systems where there is capacity to install a larger array, the lowest cost option and shortest payback will be achieved using string inverters.

Conclusion

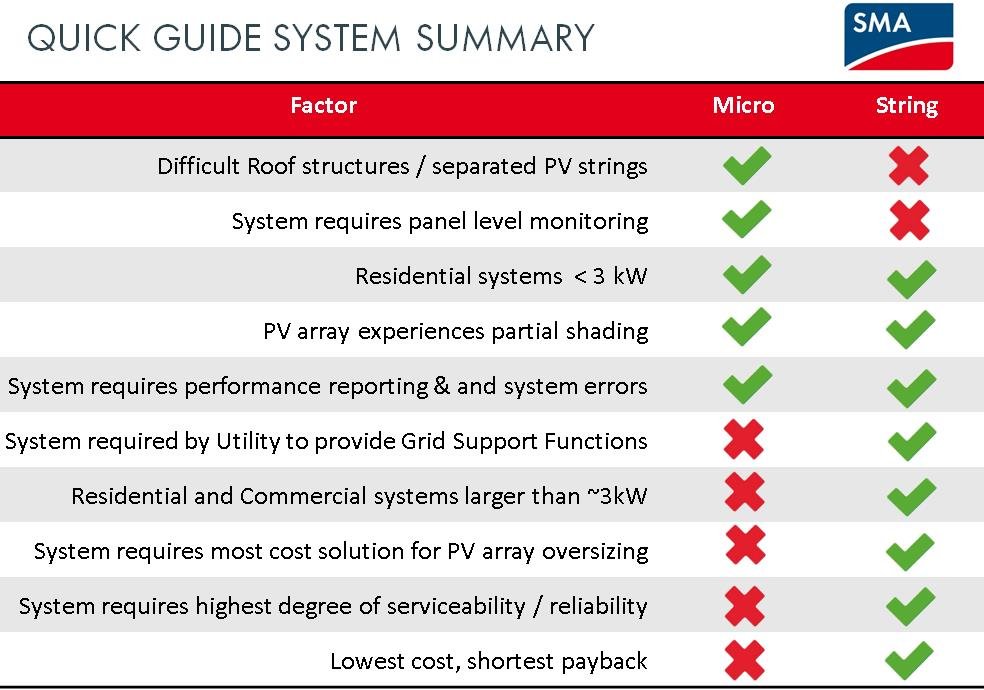

There are many factors which need to be considered when designing and installing PV systems. SMA is almost unique in the PV industry as manufacturers of the full range of inverter technologies (micro, string & central). SMA’s main goal in this regard is to ensure systems are designed using the most appropriate inverter technology. Factors including feature requirements and installation flexibility, PV array oversizing, performance and shading, service and reliability, and payback time all impact the decision of whether to build a system using micro or string inverters. A simple guide is that for systems sizes up to 3 kW or for systems which require a great degree of flexibility installing on different roofs and array orientations, a micro inverter system can offer an optimal solution. In most other situations, the lowest cost, lowest risk option is to use string inverters.

Are the SMA micro inverters compatible with SMA Sunny Island used in off-grid configuration?

Best Regards,

Bruno.

Hello Bruno,

may you have a look on this pdf:

It is a list of SMA inverters, which can be used in off-grid systems.

Kind regards, Lucas

Hello,

Do you have an statistic regard the life-time of both string inverters and microinverters? I had knowledge that in an average case, you will have to replace almost all of your string inverter components after 15 years, while microinverters last for more than the tipycal 25 years of life-expectancy for a common PV system. This would mean the neccesity of consider an accountable amount of money, to cover the cost of the string inverters replacement when I elaborate my business case, while designing my PV system…

Thank you in advance.

Regards!

Hi,

Are the SMA Sunny Boy 240 Micro Inverters compatible with the SMA Sunny Home Manager, SMA Energy Meter, and SMA Radio Controlled Sockets?

Thnaks

Where can I find the data and instructions to Oversize my Sunny Boy 8000US string inverter. I currently have 3 strings of 14- 240 watt panels. My system rarely if ever nears the 8000 watt peak. When it does it is for a short period of time from the late morning to mid afternoon. It is slow to rise in the early morning and quick to drop off in the late afternoon. I would like the system to utilize more of the capacity of the inverter for a much longer period of the day. I live in Phoenix Arizona and I want to take full advantage of my Sunny Boy in our sunny state. Thank You

Thanks, Anthony Canning

Hi Anthony,

Thanks for your question.

Let me first answer with a reason why the “system rarely if ever nears the 8000 watt peak”. In short, temperature is the reason the PV array rarely reaches 8kW. According to the information you gave, you have a PV array with a DC “rated” power of 10.08kWp. But this rating assumes the PV panels are operating at 25’C (77’F), are receiving solar energy @ 1000 watts per square metre (92.9 watts per square foot), with ideal atmospheric conditions. And as lovely as the weather is in sunny Arizona, unfortunately these conditions are rarely experienced by the PV modules. As PV modules heat up, their conversion efficiency goes down. As a result, the approximate DC power of your PV array under normal operating conditions is probably about 7.6kWp. When the PV array is cooler, its performance might peak a little higher (such as early morning, or later in the afternoon as you describe). But once receiving light, the PV panels will typically heat up within 3 minutes to their nominal operating temperature which can be between 45-70’C (113-158’F), and it is this temperature which de-rates their performance (lower voltage).

The only way to utilise more of the inverter’s capacity is to re-design the PV array, most likely adding more PV modules to the system. Adding modules to your strings should be possible, providing you add modules of the same make and power and do not exceed critical inverter input parameters. The best place to start is using SMA’s FREE online system design tool, Sunny Design, to virtually re-string the system to see what types of power gains are possible given the stringing capabilities of the inverter. In this way you could also add more PV modules to see how the total energy changes. Sunny Design will take care to ensure critical input parameters to the inverter are not exceeded, the most important of which is maximum voltage.

Finally, I can also suggest that you may wish to engage the services of a suitably qualified solar system designer to assist. And if it does transpire that your system is re-configured or altered, make sure this is done complying with all local electrical regulations.

Thanks for your question and support of SMA.

Best regards,

Scott

We installed 2 systems at the same day last week, one with micro inverters and one with a SMA Sunny Boy 1.5 kW. Both systems have the same panel manufacturer.

The micro inverter system (not from SMA) took pretty long to set-up in terms of configuration of the monitoring and detecting the devices.

The monitoring of the SMA string inverter system was much more straight forward and much much quicker. Great that the new little Sunny Boys have Wi-Fi now.

In terms of performance, the micro inverter system seems to perform very well in (partially) clouded conditions and looking at the specific output kWh/kWp it is currently performing better than the string inverter system.

However, we had many cloudy days since the install and we need to look at this over a longer period of time. Definitely an interesting development these micro’s.

I believe that the payback time graph is incorrect. As shown, the bigger the system, the longer the payback time. If this were the case, banks would not lend money for large projects.

Peter – thank you for your comment on the blog post.

The graph is meant only to be a simple representation of the cost of the system versus the system size, to give an indication of system payback for string and micro inverter systems. Perhaps the title of the graph could have been better chosen to illustrate this. Of course the payback of a system is quite an involved and varied calculation with a number of factors such as grid tariffs, local installation regulations, installer qualification requirements, cost of capital, etc. Then of course there are the different specific prices for inverters which, as they increase in kW capacity, generally decrease in their $/W. The final point to note is that different project developers and financiers have different goals, acceptable risk profiles and required internal rates of return. A system of one topology, size and method of finance might be acceptable to one set of developers and financiers but not be acceptable to another set.

Again, the main point to note is that the graph is it is only meant to help illustrate to installers and potential system owners that as systems get larger the payback time for string inverter systems will be shorter than for micro inverter systems.

Please feel free to respond if you have any other questions. – Scott

Does SMA use solid-state capacitors in their micro inverters? According to Enphase, their capacitors have a life time of 50 years based on a 4000h at 105 deg. C specification. How does the SMA capacitor compare with this?

Cheers, Udayan

Hi.

1. When will the microinverters have beeter grid flexibility. Reactive power control.

2. Why don’t the string inverters have wifi.

3. Great inverters other than the wifi.

Shouldn’t your failure graph have ?

Also, 300 years and 150 years seem like ridiculous MTBF, especially for micro-inverters exposed to the elements. If they really lasted that long, why do they only have 10-25 year warranties?

Bill, thank you for the question.

Firstly you need to remember that MTBF is only a statistical measure and does NOT mean that inverters will last for hundreds of years. When the number of inverters in a plant, or which a company may have under their O&M control is known, MTBF is able to be used to determine the statistical likelihood of failure within a given time period.

In the example in the blog post, the number of micro inverters an MTBF of 300 years was used to calculate that there could be as many as 7 individual inverter failures within the warranty period for that system.

If you want more clarification on what mean time between failure is and how to use it, I recommend reading the material on the following sites:

https://en.wikipedia.org/wiki/Mean_time_between_failures

http://world-class-manufacturing.com/KPI/mtbf.html

http://www.techworld.com/operating-systems/mtbf-what-lifespan-can-you-expect-1944/

Best regards,

Sarah