PV module optimizers are as useless as a refrigerator at the North Pole

Optimize energy yields in PV systems intelligently, but safely. When it comes to additional module electronics versus lean system design with modern inverter technology, Hannes Knopf is in his element. The expert in modern string inverter features shares his knowledge: Why do module optimizers can be a safety risk? And how do operators and installers benefit from more efficiency and safety with the integrated software SMA ShadeFix?

A study has now compared various technologies for yield optimization. In terms of energy yield, the hardware MLPE solutions performed more poorly in most cases than the software-based SMA solution. What is the reason for this?

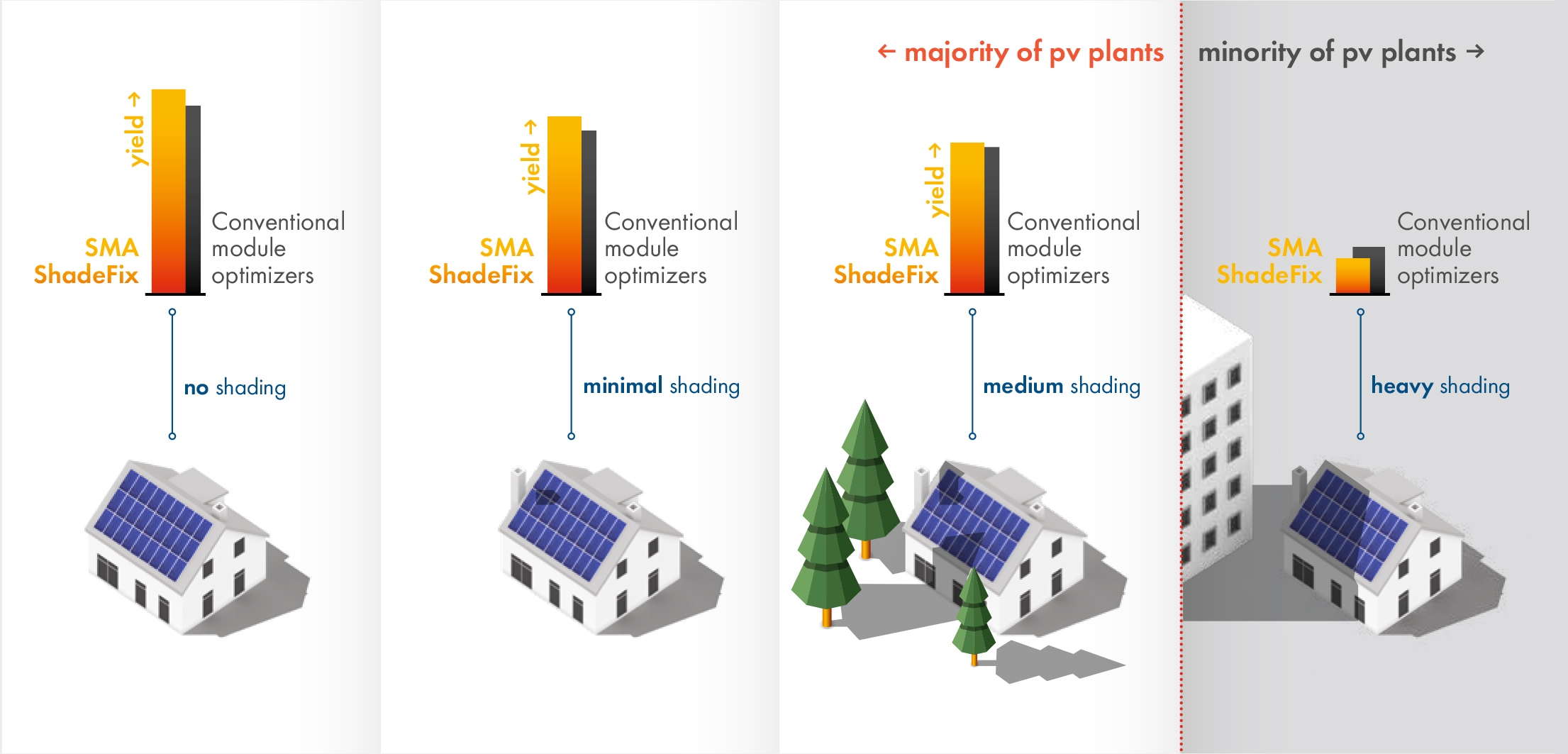

The special feature of the SMA string inverters is the integrated SMA ShadeFix function. Namely, it automatically ensures that the PV systems can convert a particularly high amount of sunlight into electric current. Even in shading. I am particularly pleased that this has now also been confirmed by a scientific study. It shows that hardware solutions for module optimization produce an additional yield only in rare cases, i.e., with very heavy permanent shading. However, for the majority of the PV systems module optimizers are as useless as a refrigerator at the North Pole.

Energy yields in the shade. That sounds a little like a paradox. How does this work?

Strictly speaking, they do not exist. At least they are usually negligibly small. This is due, in particular, to most shading on PV modules only occurring temporarily throughout the day such as in the morning or evening hours. For example, these are shadows from chimneys, dormers or trees. And this is exactly where our technology scores. It is designed to ensure that the inverter always gets the maximum power from the PV modules even when shaded.

You can think of it this way – very clear and simplified: The speed with which the electrons flow through the PV cells in the PV modules depends on the solar irradiation. In the sun, they move very fast, in the shade a lot slower. This creates an electron jam, so to speak, in the shaded part of a PV module. SMA ShadeFix bypasses the shaded part of a PV module, in which no significant energy yield can be expected anyway, and leads the electrons directly to the unshaded part. There, they can move around at normal speed. The result is more energy yield.

Module electronics to ensure more safety in the system. That is why some countries still require the use of module electronics.

The discussion about the use of Module Level Power Electronics, MLPE, for the disconnection at the module level, the so-called rapid shutdown, revolves around the safety of emergency personnel such as the fire department at a PV system. This discussion, however, completely neglects the safety of installers. The rapid shutdown regulation in the U.S. and the associated limitation of the voltage to 80 volts can lead to an incorrect assessment of the safety situation. Because even 80 volts at the PV modules is still dangerous. And who can assure that the rapid shutdown after 20 years in operation on the roof or in case of fire actually still works reliably? At the same time, a higher number of components, especially the connectors, increases the risk of fire in the system. In addition, the mandatory shutdown function at the module level completely ignores the fact that the time required for the installers on the roof is significantly increased due to the necessary components and thus their risk of accidents, for example, due to a fall from the roof.

In countries where shutdown functions at the module level are mandatory, we count on the SunSpec rapid shutdown signal standard and therefore on devices and components that are certified according to the SunSpec rapid shutdown standard. These do not require voltage converters in the power path of the module electronics which cuts down the number of electronic components on the roof by more than half and simultaneously increases the reliability accordingly. This, in turn, minimizes the risk for emergency personnel and installers on-site.

Why do you actually still need module optimizers nowadays?

Good question. The results of the study are obvious. More electronics on the roof not only increase the installation work and the probability of errors. It also means a higher risk of accidents for installers due to them having to spend more time on the roof. At the same time, a higher number of components, especially the connectors, increases the risk of fire in the system. Standard PV modules are equipped with two DC connectors. Each added MLPE device introduces four additional connectors. Tripling the contact points increases the failure and fire risk. The potential sources of danger include incorrectly mounted connectors, loose plug connections and in particular mismatching, i.e., connectors of different manufacturers.

If, however, a part of the system is heavily shaded, the selective use of a power optimizer may make sense. An especially competent installer would be needed to efficiently plan the system, as well as assessing realistically whether a PV system even makes sense at the location. There is still no technology that can turn shade into light.

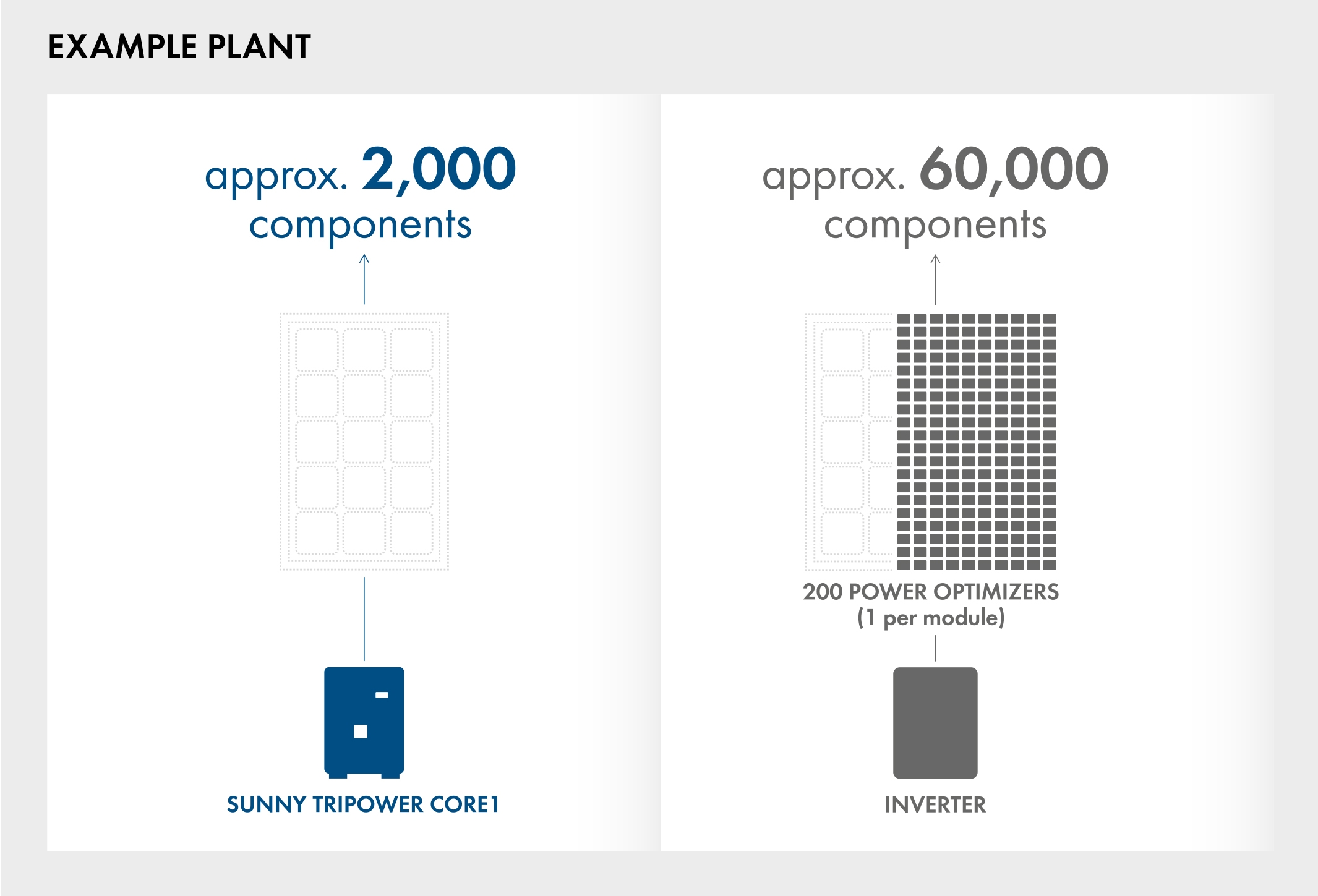

Comparison of the components for a typical commercial plant with 50 kilowatts (kW) output: Around 2,000 electronic components are required in the SMA system solution, whereas more than 60,000 electronic components are required when using module optimizers.

Maximum energy yields for the customer and maximum safety in the work environment of the PV system. How can system planners achieve this?

The solution is a system design as lean as possible. Because this exactly meets the basic requirements for a PV system, namely maximum safety requirements in the work environment of the PV system with the highest possible energy yield for the system operator throughout the entire system life. Therefore, we integrate all relevant features directly into the SMA inverter whenever possible. In this way, the software SMA ShadeFix and the service and monitoring function SMA Smart Connected optimize the energy yield over the entire life of the PV system. SMA Smart Connected proactively monitors inverter health, alerts installers to issues, and sends remediation guidance or even replacement devices automatically. This is reducing service trips.

What if the installer or PV system operator has already opted for module optimizers?

In economic terms, it is certainly not reasonable to remove all module optimizers from existing systems now. This would require installers to get up on the roof again – involving the corresponding amount of work and an increased risk of accidents. And after all, the PV system operator bears the costs. However, if the optimizers are about to be replaced, modernizing the system with modern inverter technology could be a smart alternative.

Your advice for all PV system operators or those who want to be?

Good consultation and reliable information in advance are important. Do not worry about a little bit of shade.

*The SunSpec Alliance is a trade organization comprising more than 100 solar and storage industry participants from North America, Europe and Asia. Their goal is a uniform standard for the interoperability of “plug and play” systems.

You want to know more about the comparison of SMA ShadeFix with module optimizers?

I use a mix of plain strings, strings with partial Tigo optimisers and one fully loaded with Tigo optimizers; all on SMA inverters. I think I know what I am doing, and I do not think that putting down Tigo (appears to be an SMA partner) is helpful. Both the naming ‘shadefix’ and the consistent messaging by SMA that optimizers are useless (which is only true under certain conditions) are damaging to the SMA reputation as a trustworthy source of information (imho) except among illiterates in the field of PV power generation. It would make more sense to present the truth; many sysems do not require optimizers and fare well with the SMA intelligent tracker system. However, certain systems benefit from optimizers that SMA supports through a wonderful partnership, where they are only placed where they are needed. Trust me, if the Tigo solution had not been available then in my situation there would not have been any SMA.

Interesting…but if the optimizing function is integrated in the DC/AC inverters, that usually manage kW of power, wuoldn’t be necessary a more capillar use of inverters? In cheap words, I would have to choose many little inverters rather than bigger ones, in lower number. Correct? How an inverter with ShadeFix software can influence the “path” of the electrons at single module level when electrically connected to manage many different strings?

Thank you for the information.

Hello Dario,

Sorry for the delay in getting back to you.

For further support, please contact our SMA Service.

Thanks for your patience and support!

Sunny regards

Christiane

Each solar panel produces a current proportional to the amount of light on the panel near the panel operating voltage. The bad thing about this is that if this current is low then, even when the panel is shorted, that current does not get much higher. So if one of the panels is shaded, the inverter will see the voltage drop if it pulls more current than supported by that one panel, suggesting that this is all the string can provide. However by testing at excess currents, it will see that much more could be pulled if the loss of the voltage of that one panel is accepted (that panel will then be driven backwards with voltage limited by protection diodes to near-zero). So shadefix is a smarter MPP tracker than a regular tracker and it ‘ventures around’ to see if more current at a reasonable voltage compromise is available. Having said that, as the author also stated, shadefix does this at the cost of completely loosing the output of the weak panels. That is fine if weak panels are truly weak, but not if weak panels are still at 50% of available power. For such panels, an optimizer would convert the panel output to the required current, but at half the voltage (as we cannot magically create energy) so two weak panels are still as good as one strong panel. In modern shingled panels this situation is actually very common, because internally they are really many panels in parallel and shading a part of the panel does not knock it out completely. Also in complex shading conditions, even more so with partly cloudy conditions (very common where I live) this is also very common. Long story short is that I use a mix of plain strings (SMA shadefix and all) mixed with strings with partially installed Tigo optimizers and one string with all Tigo optimizers (supported by SMA BTW). So I have to say that I find this article a bit biased and I am sure that the tests are set up to get the desired results (as also done by comptetitors that want to prove the opposite point). I would wish a more neutral approach to objectively discuss where one or the other approach makes more sense. As a last note, the naming “shadefix” initially was causing disbelief on my side, I cannot say that is a very elegant choice because it induces skepticism more than anything else at first (check the internet), until I found out what it really is. Nevertheless, also my thanks for the information kindly provided.

If my rooftop system requires rapid shut down modules (approx. $35 US each), and optimizers can not only address shade, but also offer individual performance monitoring for around $10 more (approx. $45 US), then the refrigerator is now in the desert and it’s full of cold drinks.

i want some idea of solar plant

Hi Mynul,

That’s probably a good idea:-) You can either try our planning software Sunny Design or find a professional PV installer near to you.

Kind regards,

Anke